Food-safe Wood Finish For Butcher Blocks And Boards, Bowls, And More

Share it

Using blocks, boards, and blocks in preparing food nowadays seems inevitable. People are becoming more cautious about the foods they eat due to the high levels of toxic chemicals and toxins in almost everything.

There are many food-safe wood finishes available for DIY wooden utensils or bowls. You wont worry about the risks of toxins with these finishes:

9 Food-Safe Wood Sealers And Oils

There are many options on the market that are unblended and naturally sourced. They also come with no hidden ingredients and are non-toxic.

: Tung Oil

Pure tung oils is one of the safest food finishes. It is a non-toxic and eco-friendly finish from a China wood tree nut.

Another option you can try is Danish oil, a combination of pure tung oil and varnish. Danish oils offer excellent protection against water and moisture.

Advantages

- Durable, flexible finish

- It has a water-resistant and film-forming finish that protects wood from mold and moisture

- Easy to clean

- Non-drying oil, which gives off a transparent, wet appearance when hardened

Linseed Oil

Linseed oil comes from pressed flax seed. It has been listed as a food additive by the Food and Drug Administration (FDA). It is a slow-drying oil that gets washed off with water, so frequent re-application is needed.

Compared to raw linseed oil from flax seeds, boiled linseed oil is processed using oxidation, making it unsuitable as a finish for wood.

Advantages

- It provides a low luster effect on wood and enhances its natural color

- Can afford decent moisture protection

- Several coats can prevent wood stain

: Shellac

Shellac is a non-toxic and all-natural surface sealer produced from the Asian Lac bug.

There are two forms: the liquid and flake versions. These can be found in hardware stores and art supply shops.

Super Blond Shellac is the most water-resistant variety used for wood finishes.

Advantages

- Produces a film-forming glossy finish that is quick drying

- Easy to apply

- Provides good moisture protection

- UV Rays Resistant

: Food-Grade Solid Beeswax

Food-grade beeswax is an eco-friendly finish. The mixture of mineral oil and beeswax can create a more fragrant and water-repellent wood finish by sealing the woods pores.

Advantages

- Seal old scratches and sun-damaged wood surfaces.

- Water-repellent and protects against molds, rots, and fungi spores

- It’s easy to apply

- It gives wood projects a warm, glossy film-forming finish

: Walnut Oil

Walnut oil is made from pressed walnut seeds. It can also be used to finish wood. Walnut oil can also be purchased in many health food stores and markets as a salad oil.

Advantages

- Provides high water and alcohol resistance

- Can be used to produce wood with high-quality decorative and multicolored finishes

- Does not spoil

- Walnut oil dries slowly on the wood’s surface.

- Hardens into a hard resin, satin-like finish for wooden bowls and utensils

Mineral Oil

Food-grade mineral oil is sold as a laxative in drugstores and wood finish in hardware stores. Mineral oil finishes are not waterproof and can’t protect wood bowls against scratches.

The fragrant smell from adding lemon essential oil to various mineral oils provides such a pleasure when applied on wooden surfaces.

Advantages

- Odorless, tasteless, and colorless

- Do not spoil

- It is easy to use and conditions the wood, which enhances its natural grain.

- Water-based wood stains can be treated with effective overcoats

Coconut Oil

Coconut oil is all-natural and eco-friendly.

Advantages

- It doesn’t get old

- This oil has a light protective coating that prevents chipping of the cutting board or other wood surfaces susceptible to impact.

Paraffin Wax

Paraffin wax is made from the extraction of distilled petroleum. Not all paraffin wax can be consumed.

Advantages

- Used as a coating in the canning industry

- Water-resistant finish that does not affect the previous finishes on any wood surface

: Carnauba Wax

Carnauba wax, also known as Brazilian wax or palm oil, is a byproduct from a Brazilian palm tree. It can also be blended with other finishes for a more waterproof coat.

Advantages

- Use it as a finish alone or in combination with other finishes.

- More water repellent and rigid than beeswax

- Creates a shiny wax finish on wood

- When applied correctly, can create a satin-like finish (up to three coats).

What Wood Finish Should I Choose?

The level of toxicity, curing times, and method of application are all important factors to consider when choosing the best food-safe finish.

The curing time for each type of wood finish is different and should also be kept in mind when choosing the right type of finish.

Choosing Between Penetrating Oils And Surface Sealers

Penetrating oils are different from surface sealer films finishes in that they can soak into wood grains.

Surface Sealers Used Today

These food-safe finishes remain on the surface of the wood and can be built up for a more protective effect but require a more complicated application process.

Here are some examples:

- Shellac

- Beeswax

- Carnauba wax

Penetrating Oil (Drying and Non-Drying)

Penetrating oils soak the wood grains. Although this is easier to apply and provides a more natural finish, it only offers a low level of protection.

When the wood curing process is complete, these oils become solid. Polymerization is also known as drying penetrating oils. It begins when the oil is exposed to oxygen. Some of the examples of drying penetrating oils are:

- Tung oil

- Walnut oil

- Linseed oil

These oils stay wet indefinitely and are transferred when the wood surface is used. These are some examples of dried penetrating oils:

- Coconut oil and mineral oil

Heat Capacity

When choosing a food-safe finish, it is important to consider the ability of the finish’s finish to withstand extreme temperatures. High temperatures can be tolerated by tung oil and mineral oil, which are more resistant than wax wood finishes.

Curing

Before a product can be used, it must be cured. Curing assures that the wood will dry from its surface to the deepest penetration spots.

Oil wood finishes made from natural ingredients like tung oil, beeswax or shellac do not require curing and can be used immediately.

Oil Shelf Life

Unlike mineral oil, the oils produced from the extracted vegetable fats are unsafe and tend to go rancid. Hence they are not used as a finish for wooden surfaces.

Vegetable oils can remain on wood surfaces and cause off-taste in foods when used with utensils. Therefore, when purchasing oil finishes, check their expiration date.

Toxicity Levels

Good ventilation in the workplace and proper breathing protection equipment like a respirator can address the toxicity concerns during the application and curing process.

Tung oil, shellac and water-based food safe wood finishes are the least toxic. They can be used to make toys and wood items. On the other hand, lacquers are the most toxic finish and should not be used.

What Do Food-Safe Finishes Mean?

Modern wood finishes can only be considered food-safe if the application and drying processes are done properly and completely.

Food and Drug Administration (FDA), is the regulatory agency that ensures food safety. It considers the commercially available wood finishes as food safe only when they are approved for contact with food.

The FDA approval of food-safe wood finishes means that the molecules from the finish are safe for consumption or that the molecules that leach into food when these utensils are used are so tiny that the body can flush them.

One example of food-safe epoxy resin is the Stone Coat Art Coat Resin. This resin can be used to coat a cuttingboard for light-duty cutting.

The Best Wood Finish Recipe And How To Make It Yourself

A homemade wood finish is easy to make and requires only simple ingredients and 20 minutes of your time.

The ingredients would include:

- 5 tablespoons of beeswax melted

- 2 tablespoons organic coco oil

- Six tablespoons of walnut oil

- 3 capsules of vitamin E

- teaspoon orange essential oil

Begin by preparing the beeswax, coconut and walnut oils. Next, heat the mixture in a saucepan over medium heat until it is completely melted.

Mix the melted oils in the double boiler. Then, add the vitamin E oil and orange essential oil to a small jar.

How To Oil Finish Wood Surfaces

Lint-free rags and nitrile gloves are highly recommended for applying penetrating oils (both drying and non-drying oils). You can either pour the oil directly onto the wood surface or rub it on with a rag in the same way as the wood grain.

After soaking for 10 minutes, any oil that remains should be removed with a clean cloth. Smoother wood finishes can be achieved by using 400- or 600-grit dry/wet sandpaper. After the previous coat has dried to the touch, you should apply another coat.

How To Safely Dispose Of Oil Finish Rags

The rags used when applying drying penetrating oil can have heat build-up, enough to reach the point of spontaneous combustion, causing the rag to catch fire. There are a few steps to dispose of them to prevent combustion or fire:

First, the used rag should be draped on the edge of a 23 Liters metal bucket in the middle of the floor with good airflow. After drying for a few days, you can place the rag in the bucket. Wait for a week before you put it in the trashcan.

Finally, ensure that the used rag is disposed of properly in the bin or container.

Wood Finishes That Should Be Used With Caution

Vegetable Oils

Some vegetable oils, such as olive oil, can go rancid or lose their shelf life. Vegetable oils applied to wooden kitchen utensils such as cutting boards can lead to a cloudy appearance and eventually discoloration.

This oil coating on wood surfaces is also difficult to remove and may result in an off-wood taste when these utensils are used.

Lacquer

Lacquers require a long curing time and can only be considered a food-safe finish when the coating is fully matured and cured.

Lacquers are only meant to sit on top of wood surfaces. They do not penetrate wood grain. This causes lacquer coat chips to smear when they are applied too hard. This disadvantage makes it unsafe to be used as a coating on cutting boards and serving trays.

Polyurethane

Polyurethane creates a transparent, hard coat on wood that is water- and abrasion-resistant. However, because of its long curing time (approximately 30 days), people used metallic driers on it to reduce the drying time.

Metal driers can be considered a pollutant, and pose a significant health risk when used on wooden cookware and kitchen utensils.

FAQ

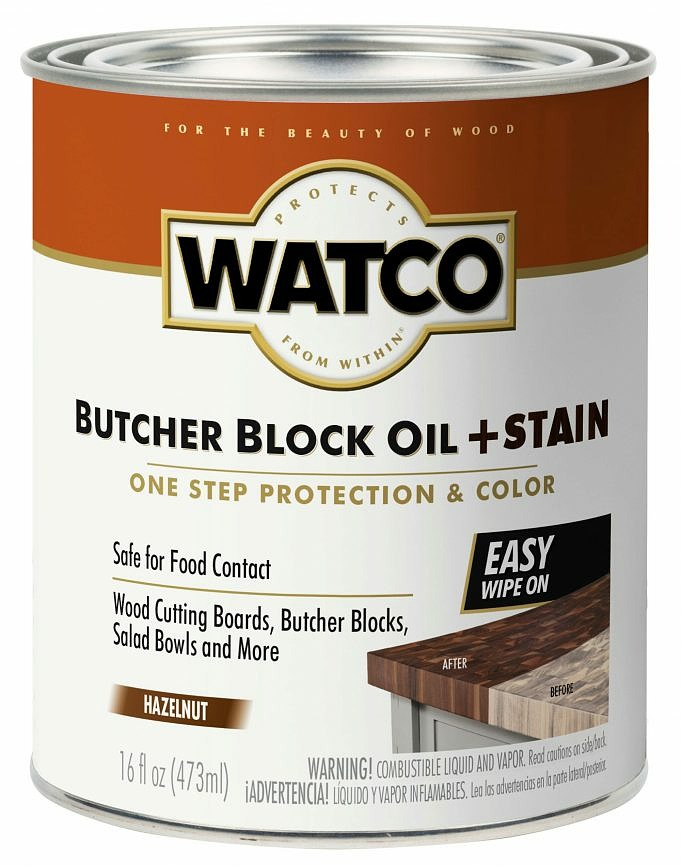

What is the food-safe stain I can use for butcher block countertops?

Butcher Block Oil + Stain is a food-safe stain for wood countertops. These specifically formulated products are safe for staining cutting boards and wooden butcher blocks.

What oils and sealers are available to restore my wooden kitchen tools?

Wooden kitchen tools can be refilled with mineral, walnut, or tung oil. These oils can be used to refresh wood projects, such as wooden bowls, cutting boards or salad bowls.

Conclusion

When choosing a food-safe wood finish, one should consider various factors like curing time, heat capacity, and toxin levels. Some wood finishes that should be used carefully are lacquer, polyurethane, and vegetable oils.

It is easy and cheap to make a wood finish at home. It only requires a few ingredients, such as beeswax, and instruments like a double boiler and glass container.